In the past decade, construction has shifted from traditional, paper-based management to a fully connected digital environment. Technology integration has become more than a convenience—it’s the backbone of modern construction management. From project estimation and scheduling to on-site coordination and data-driven decision-making, digital construction tools are redefining how buildings are designed, built, and maintained.

This article explores how technology integration is shaping digital construction, the tools driving this revolution, its benefits, challenges, and what the future holds for the industry.

1. Understanding Digital Construction

Digital construction is the process of using digital tools and data-driven technologies to improve the planning, design, construction, and operation of a building. It bridges the gap between the physical and virtual worlds, allowing teams to simulate, predict, and optimize every step before the first brick is laid.

This concept doesn’t only apply to high-tech firms or massive infrastructure projects. Even small contractors are adopting digital construction methods to improve efficiency, accuracy, and profitability. The goal is simple: reduce waste, save time, and deliver higher-quality outcomes.

2. The Core Technologies Driving Digital Construction

2.1 Building Information Modeling (BIM)

BIM serves as the foundation of digital construction. It creates intelligent 3D models that contain physical and functional details about a building. Estimators, architects, and engineers collaborate in real time within the same model—making changes visible to everyone instantly.

BIM integration with cost estimation software allows for real-time quantity takeoffs, material tracking, and budget forecasting, eliminating many of the manual errors found in traditional processes.

2.2 Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are powering predictive analytics, risk assessment, and cost forecasting. Estimators can use AI tools to analyze historical data and generate more accurate cost projections. AI-driven scheduling and safety management tools can identify inefficiencies and predict delays before they happen.

For instance, an AI-powered estimator can automatically calculate labor, equipment, and material costs using past project data—allowing firms to bid more competitively without sacrificing accuracy.

2.3 Drones and Aerial Mapping

Drone technology has evolved from novelty to necessity in modern construction. Drones capture high-resolution aerial imagery and topographic data, offering real-time site monitoring, material tracking, and safety assessments.

Integrating drone data into construction management platforms ensures accurate progress tracking and site analysis—especially for large or complex projects.

2.4 Internet of Things (IoT)

IoT connects physical construction equipment, tools, and sensors to digital systems. Smart sensors can monitor concrete curing, humidity, equipment usage, and worker safety. This real-time data gives project managers actionable insights, reducing downtime and improving site efficiency.

IoT is particularly transformative for predictive maintenance—alerting teams when a machine or tool is about to fail before it causes costly project delays.

2.5 Cloud Collaboration Platforms

Cloud-based tools like Procore, PlanHub, and ConstructConnect enable instant document sharing, bidding, and communication across stakeholders. Every update—whether a drawing revision or schedule adjustment—is instantly available to everyone.

The result: less miscommunication, fewer reworks, and faster decision-making.

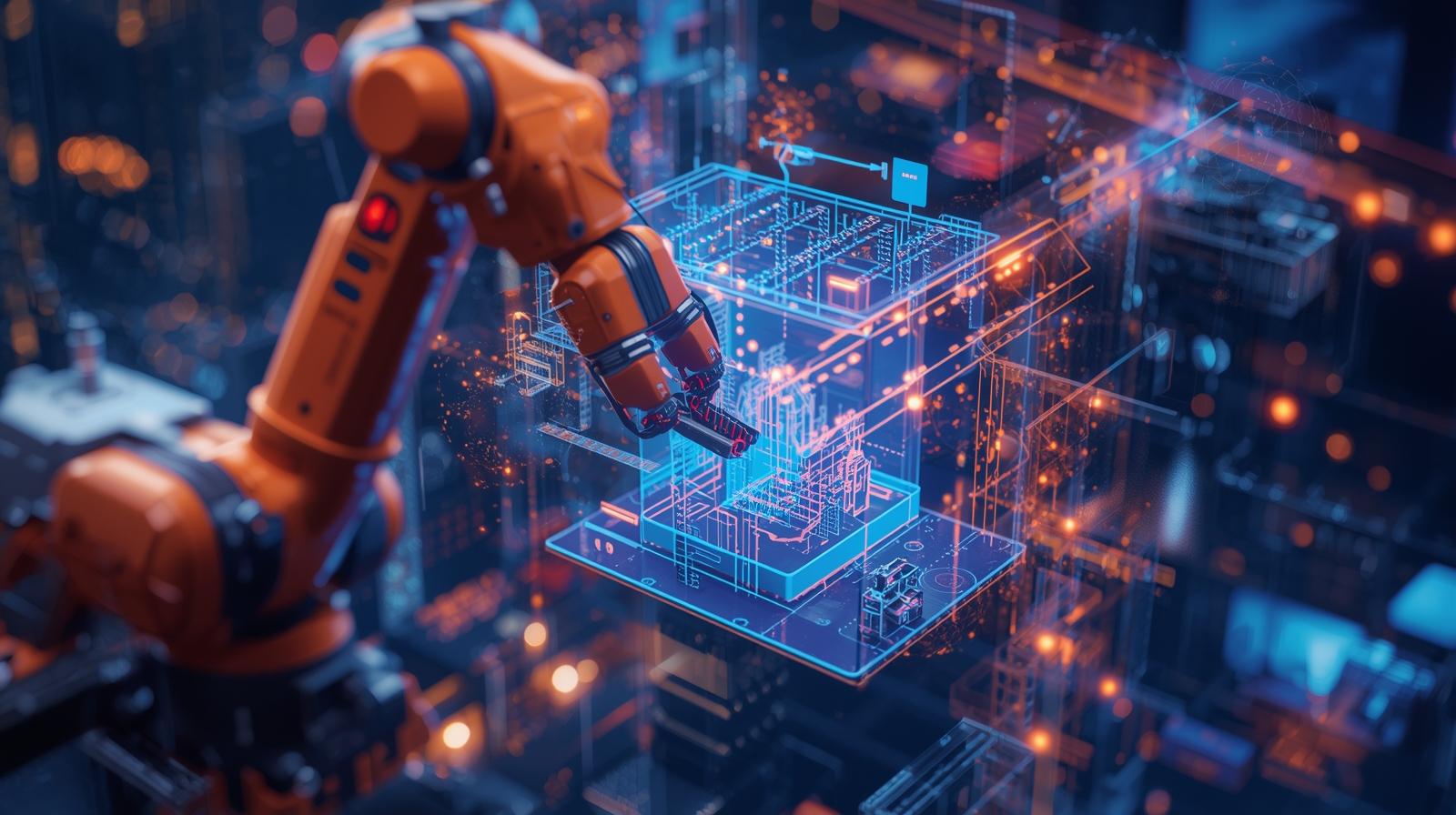

2.6 Robotics and Automation

Robotics are being deployed for tasks such as bricklaying, concrete pouring, and material transport. Robots not only improve productivity but also reduce the safety risks associated with repetitive or hazardous work.

3D printing, a form of automated construction, is also gaining traction. It allows for quick, precise, and cost-effective building fabrication directly from digital designs.

3. Benefits of Technology Integration in Construction

The integration of digital technologies offers benefits that extend across every phase of construction.

3.1 Greater Accuracy in Estimating and Planning

Digital tools eliminate guesswork from the estimating process. With real-time data and AI-assisted calculations, cost estimators can generate precise, up-to-date project budgets and material lists.

3.2 Improved Collaboration and Communication

By connecting all stakeholders through centralized platforms, digital construction ensures that everyone—architects, engineers, contractors, and clients—has access to the same information. This reduces misunderstandings, costly errors, and rework.

3.3 Faster Project Delivery

Automation and real-time coordination streamline every step, from design approval to procurement and scheduling. Tasks that used to take days can now be completed in hours with the right digital workflow.

3.4 Enhanced Safety and Risk Management

IoT and AI systems continuously monitor construction sites to identify unsafe conditions, predict hazards, and alert supervisors. This proactive approach reduces incidents and ensures compliance with safety standards.

3.5 Data-Driven Decision Making

Digital tools collect vast amounts of data that can be analyzed to improve future performance. Construction managers can assess productivity trends, track equipment efficiency, and make evidence-based improvements for subsequent projects.

4. Challenges in Technology Integration

Despite the advantages, digital transformation in construction is not without challenges.

4.1 High Initial Costs

Investing in digital software, hardware, and staff training requires upfront capital. Smaller firms may hesitate to adopt these systems due to budget constraints.

4.2 Workforce Training and Adaptation

The construction industry has a reputation for traditional work practices. Training employees to adopt new tools and digital workflows can be time-consuming, and resistance to change is common.

4.3 Data Security Concerns

As construction firms rely more heavily on cloud platforms, data protection becomes a serious issue. Sensitive project data and financial information must be secured from cyber threats.

4.4 Integration Compatibility

Different tools often use different data formats. Integrating BIM, estimating software, and project management systems seamlessly remains a challenge, requiring standardization across platforms.

5. Real-World Applications of Digital Construction

- Prefabrication and Modular Building: Digital modeling ensures components are pre-built to exact specifications, reducing waste and on-site time.

- Smart Construction Sites: IoT-enabled sites track worker movements, equipment use, and environmental conditions in real time.

- Digital Twin Technology: Virtual replicas of buildings help monitor asset performance post-construction, improving facility management and long-term maintenance.

- Automated Estimating Systems: Integrated tools like Autodesk Construction Cloud and ProEst allow cost estimators to pull quantities directly from BIM models, ensuring up-to-date pricing.

These examples prove that digital construction is not just about technology—it’s about efficiency, sustainability, and informed decision-making.

6. The Future of Digital Construction

The future points toward fully connected ecosystems, where every piece of data—from design to demolition—is integrated into a single digital thread. AI will evolve from predictive analytics to prescriptive decision-making, automatically suggesting the most efficient solutions.

We’ll also see more emphasis on sustainability. Digital tools will help measure carbon footprints, optimize energy use, and promote eco-friendly material selection.

As robotics and 3D printing mature, construction will become faster, safer, and more precise. And with the growing influence of augmented reality (AR) and virtual reality (VR), professionals will soon be able to visualize full projects in immersive environments before construction even begins.

7. Conclusion

Technology integration in digital construction is transforming the way the industry operates—from the drawing board to the job site. By connecting data, people, and processes, these tools eliminate inefficiencies and improve every aspect of project delivery.

Firms that embrace digital transformation early will not only gain a competitive edge but also build more sustainable, profitable, and resilient operations. The construction world is evolving fast—and those who adapt will define the future.